Core Manufacturing Capabilities

Precision Manufacturing Excellence

End-to-End Precision Manufacturing

TecoStar Holdings delivers a complete suite of precision manufacturing services that span machining, forming, finishing, engineering, and clean room assembly. Our teams support regulated programs across medical devices and aerospace & defense with robust process controls and traceability.

Every capability is built on rigorous quality systems, digital work instructions, and continuous improvement to safeguard performance for mission-critical components.

Capability Matrix

Specialized processes that keep medical and aerospace programs production-ready

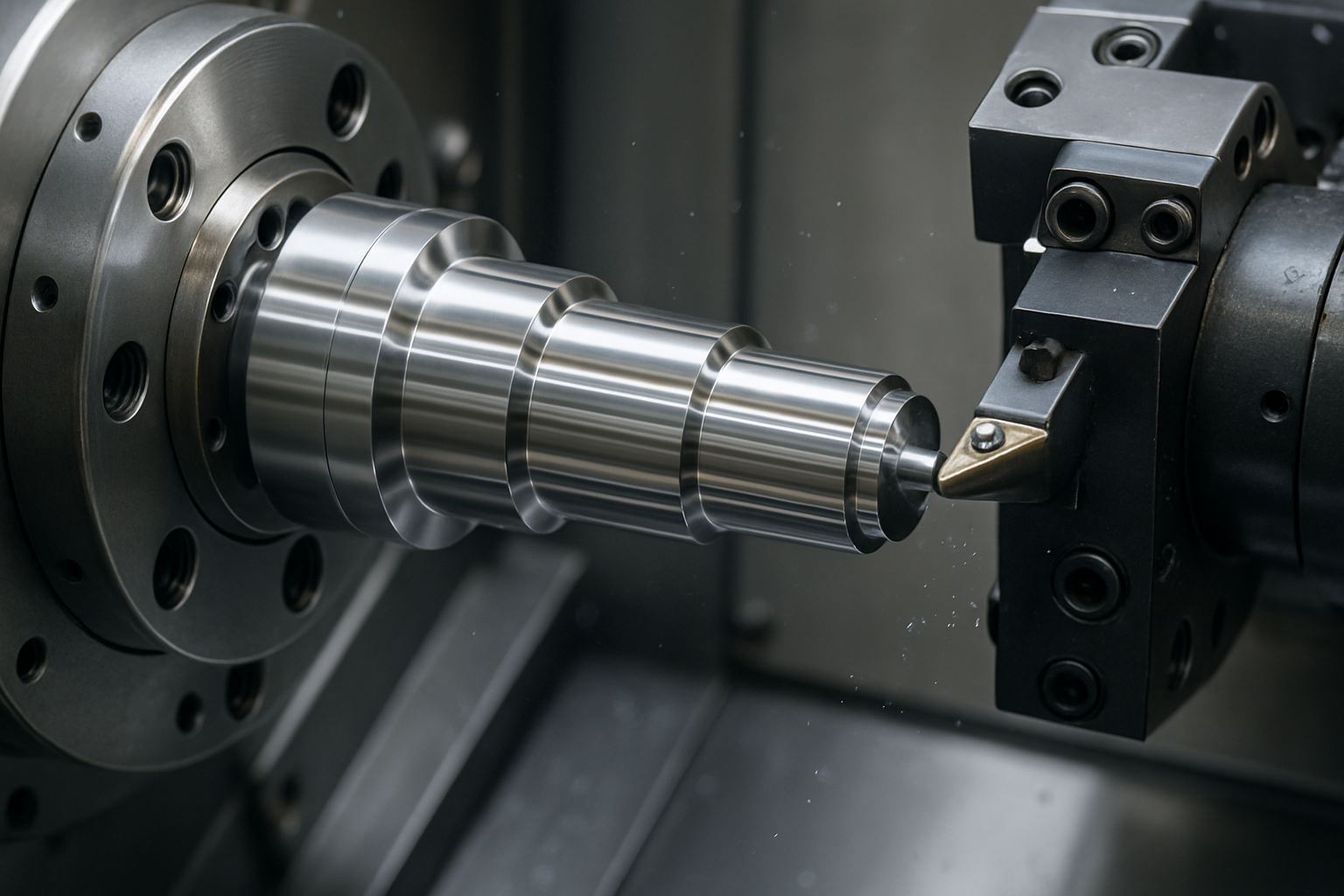

Precision Machining

CNC milling, turning, grinding, and EDM with micron-level tolerances for complex geometries.

Forging & Casting

Closed-die forging and precision casting for aerospace-grade alloys and medical materials.

Finishing & Coatings

Passivation, anodizing, polishing, and specialty coatings tuned for performance and longevity.

Engineering Support

Design for manufacturability, rapid prototyping, and validation to accelerate program launches.

Clean Room Assembly

ISO-certified clean room assembly, packaging, and final inspection for sterile devices.

Quality & Testing

Metrology, NDT, and documentation aligned to ISO 13485, AS9100, and FDA requirements.

Certified for Critical Programs

Compliance-first operations for medical devices and aerospace platforms