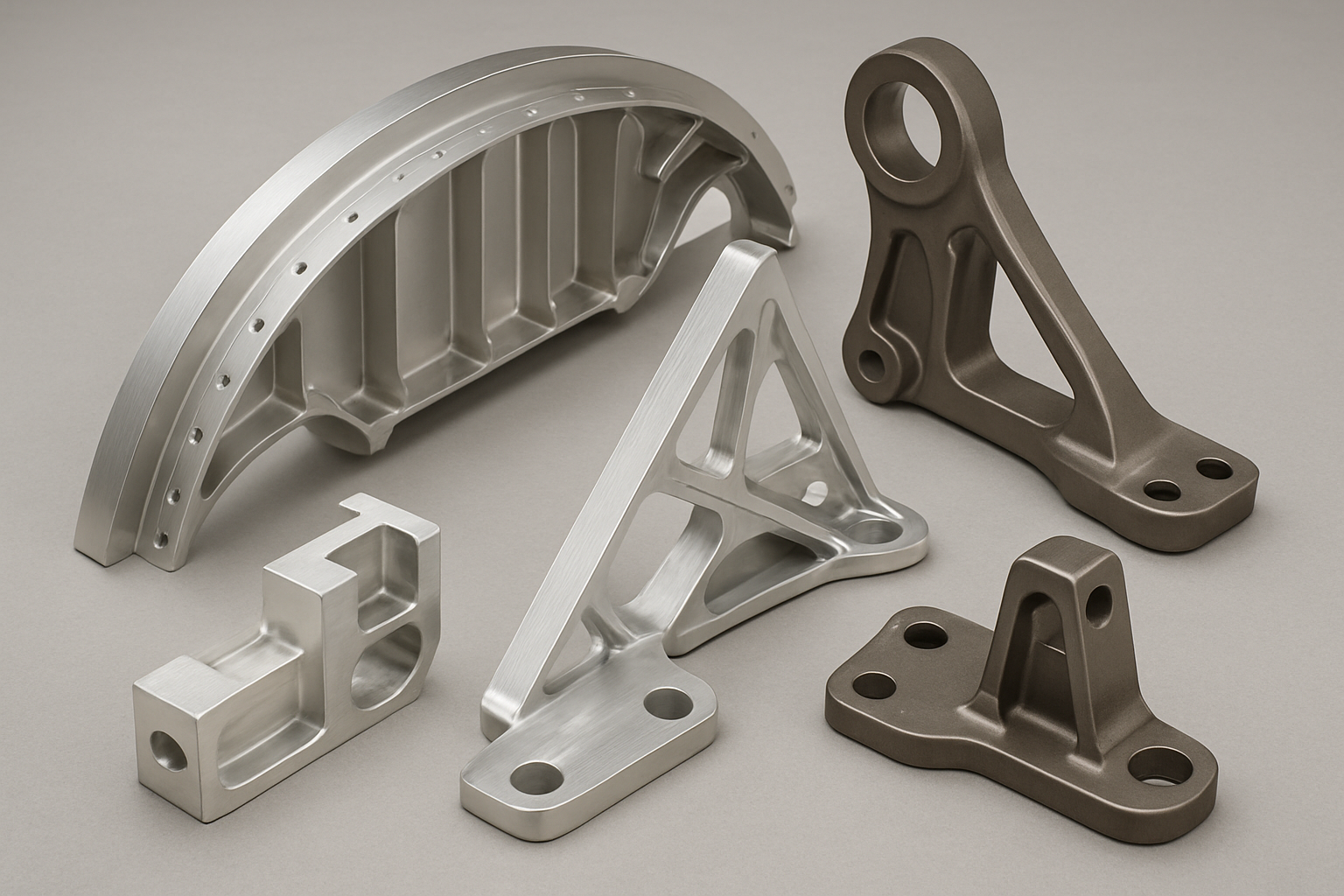

Forging & Casting Services

Structural integrity for aerospace and medical applications

Engineered Metal Forming

Closed-die forging and precision casting deliver superior grain flow, strength, and reliability for mission-critical parts. Our process controls protect dimensional accuracy while ensuring repeatability across production lots.

- Closed-die forging for high-strength geometries

- Investment casting for complex, lightweight forms

- Material certifications and full traceability

- Integrated heat treatment and dimensional control

Process Advantages

Strength, consistency, and compliance built into every lot

Materials

Aluminum, stainless, titanium, nickel alloys, and cobalt-chrome engineered for aerospace and implant-grade applications.

Heat Treatment

Controlled heat treat cycles and hardness verification aligned to program specifications.

Validation

NDT options, metallurgical analysis, and PPAP/FAI packages for regulated programs.