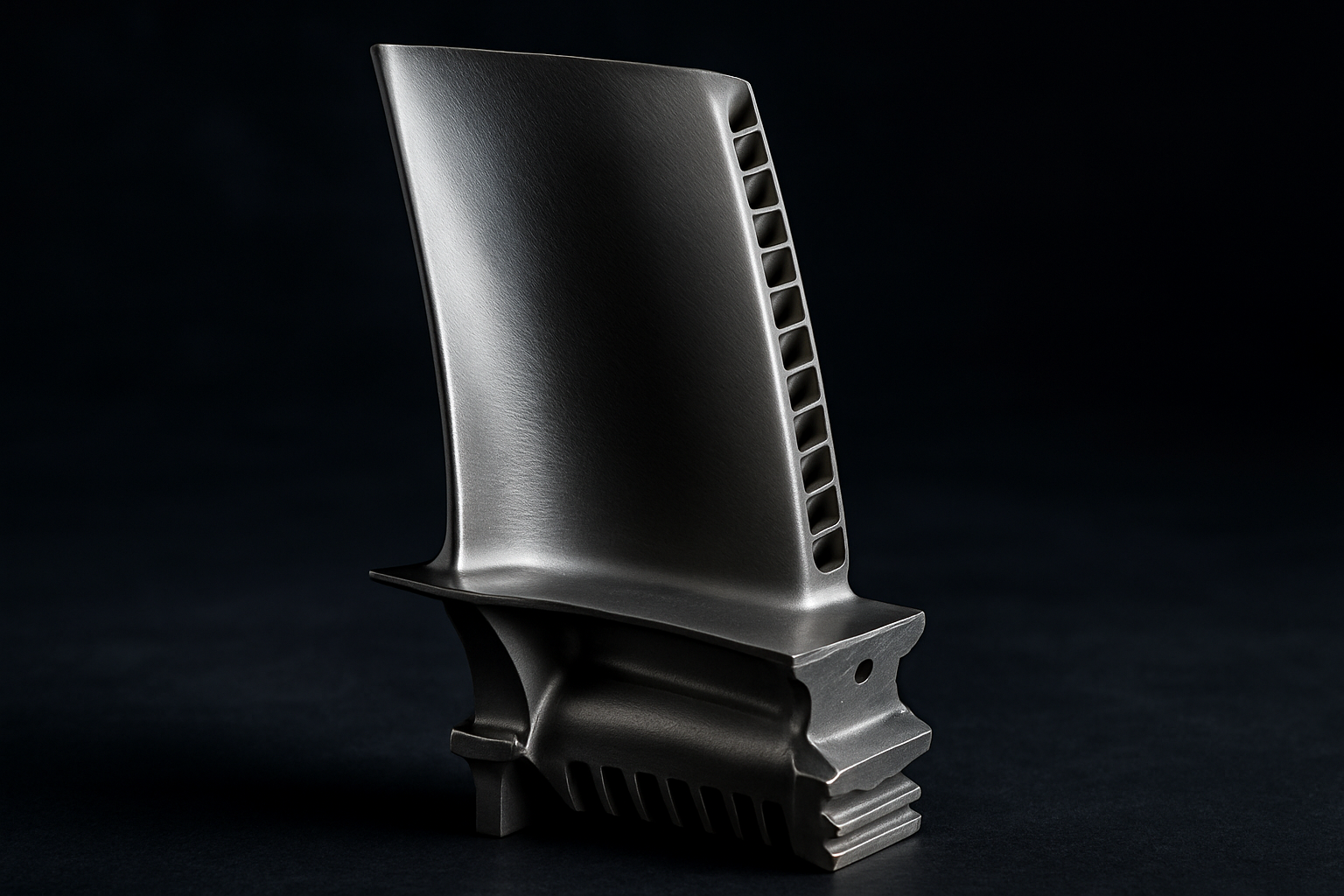

Aircraft Engine Components

High-temperature alloys, precision machining, and validation

Propulsion-Ready Manufacturing

We produce tight-tolerance engine components for commercial and defense propulsion systems. Process control plans cover temperature management, tool life, and in-process inspection to protect dimensional integrity.

- Turbine blades, vanes, and compressor hardware

- High-temperature nickel and titanium alloy expertise

- Balancing, surface finish, and concentricity controls

- Serialization, traceability, and material certifications

Engine Program Support

Quality, validation, and supply chain discipline

Process Validation

FAI, PPAP, and capability studies to validate new part introductions and engineering changes.

Metallurgy & Testing

Metallurgical review, hardness testing, and NDT coordination for fatigue-critical parts.

Program Management

Dedicated teams for scheduling, configuration control, and secure data handling under ITAR.